DELIVERY just £9.95

9937 Hoffmann Frame Joiner Heavy Duty

Specification: Heavy Duty

9937 Hoffmann Frame Joiner Heavy Duty

For joining hard wood picture frame profiles by routing a slot for a dovetail key

Getting a tight join on dense hard woods such as oak and walnut can be a struggle because underpinners need to displace timber fibres as the v-nail is inserted. If you make a lot of frames with these timbers, the Hoffmann Frame Joiner Heavy Duty is a great alternative because it works completely differently - by routing a slot for a dovetail joining key.

Once tapped into place, the key pulls the corner tightly together. The Hoffmann Frame Joiner Heavy Duty is especially useful for getting a great join on tall, narrow moulding profiles and the robust construction means it’s perfect for higher volume work.

Features

- Powerful 1000 watt milling unit routs any hard wood with ease.

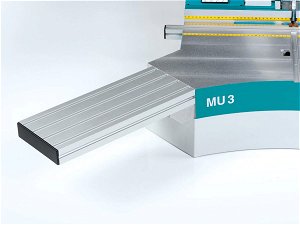

- Heavy duty build for higher volume work. Cast aluminium base with large, ergonomically shaped table surface, precision linear bearings, galvanized steel motor carriage and an integrated motor fine with adjustment.

- Higher back fence and larger hold down plate compared with Hoffmann Frame Joiner to support taller mouldings. Longer, more robust lever to apply more pressure.

- Height extensions and support wings available for taller, larger frames.

- Fully adjustable base plate for the thinnest of frames.

- Supplied with W1 router bit. Size W0 & W2 bits and keys also available. Tungsten Carbide router bits have an approximate life of around 10,000 strokes.

- Max routing depth 85mm, max moulding height 130mm.

- 37mm dust extraction port fits most commercial vacuum cleaners with no adaptor.

- Does not require a compressed air supply.

- Operates on a standard 13a power supply.

- Made in Germany.

How does the Hoffmann Frame Joiner work?

- Set the router depth according to the size of key.

- Position the slot - lay a piece of mitred moulding on the bed and line up the slot location with the indicator on the machine. Slide up and lock the centre fence plate.

- Place the mitred piece to be routed on the left side of the bed with the rebate facing away.

- To start the machining cycle, pull the lever.

- Padded hold-down plate clamp secures moulding and motor is switched on. Continue pulling the lever to advance the router head until pre-set height is reached.

- Release the lever to return the router to its home position, shut off the motor and release the moulding.

- Move the mitred piece to the right side of the bed to rout the other end. Repeat for all four mitred pieces.

- When all four mitred pieces are routed at both ends, taps the keys into place with a soft hammer.

Specifications

Power supply: 1ph/N/PE 230 V 50/60Hz 1.0 kW

Motor: 1 x 1000 Watt

Motor speed: 34.000 1/min

Height capacity: 130mm

Routing depth: 0-85mm

Extraction port: 37mm diameter

Hoffmann key sizes: W-0/1/2/3

Dimensions B/W/H: 740 / 650 / 835 mm

Weight: 32kg

See also:

Choosing new framing equipment?

Our experienced Technical Team can help you choose the right framing equipment for your workshop, whether you’re just starting out or thinking of upgrading. They can also assist with installation, servicing and spare parts. Just email techserv@lionpic.co.uk or call 0121 773 1230.

We can also help you spread the cost of professional framing equipment over 3 or 6 monthly instalments, find out more:

• 3 instalments made 30, 60 and 90 days from invoice at 0% interest on equipment over £1000.

• 6 instalments made 30, 60, 90, 120, 150 and 180 days from invoice at 0% interest on equipment over £2000.

• You’ll need to open a credit account to apply.

• All goods remain property of LION until paid in full.

• Our Terms & Conditions apply.

For higher value purchases we also work with Kennet Leasing, allowing you to spread the cost over 3-5 years. We take no commission so you get the best deal. Find out more: Kennet Equipment Leasing

Also in the Range View Range

Available to order.

Lead time approx. 3 working days. Contact sales team for further info.

Available to order.

Lead time approx. 3 working days. Contact sales team for further info.

Questions

Please feel free to ask any questions about this product.